Dear customer,

Thank you for your interest in our products. We would like to provide a brief overview of our company. In 1992, Friedrich Motorsport was founded by owner Dirk Friedrich. At first operations were concentrated on engine modifications, repairs and machining, complete vehicle and exhaust system rebuilds, and various tuning accessories. Over the years, the company continued to grow. Starting in 2005 management decided to focus on the broad area of exhaust systems. Friedrich Motorsport now consists of two company headquarters with about 30 employees, one where we perform development work and manufacturing, and the other with sales, more manufacturing, and customer service. Sincerely, The Friedrich Motorsport Team

A QUICK LOOK AT PRODUCTION

- Factory

- Production

- Pipe bendingarea

- Bending machine

- Warehouse

- Coating

- Finished parts andshipping

- Welding place

- Intermediate storage - Silencer

- Shipping

Factory

The beginning and the end, combined in one of our factories. Here we build prototypes and new designs and assemble finished systems from our warehouse.

Production hall

Short distances are the key to a quick order processing. Everything comes together here. The raw material is right next to the processing machinery.

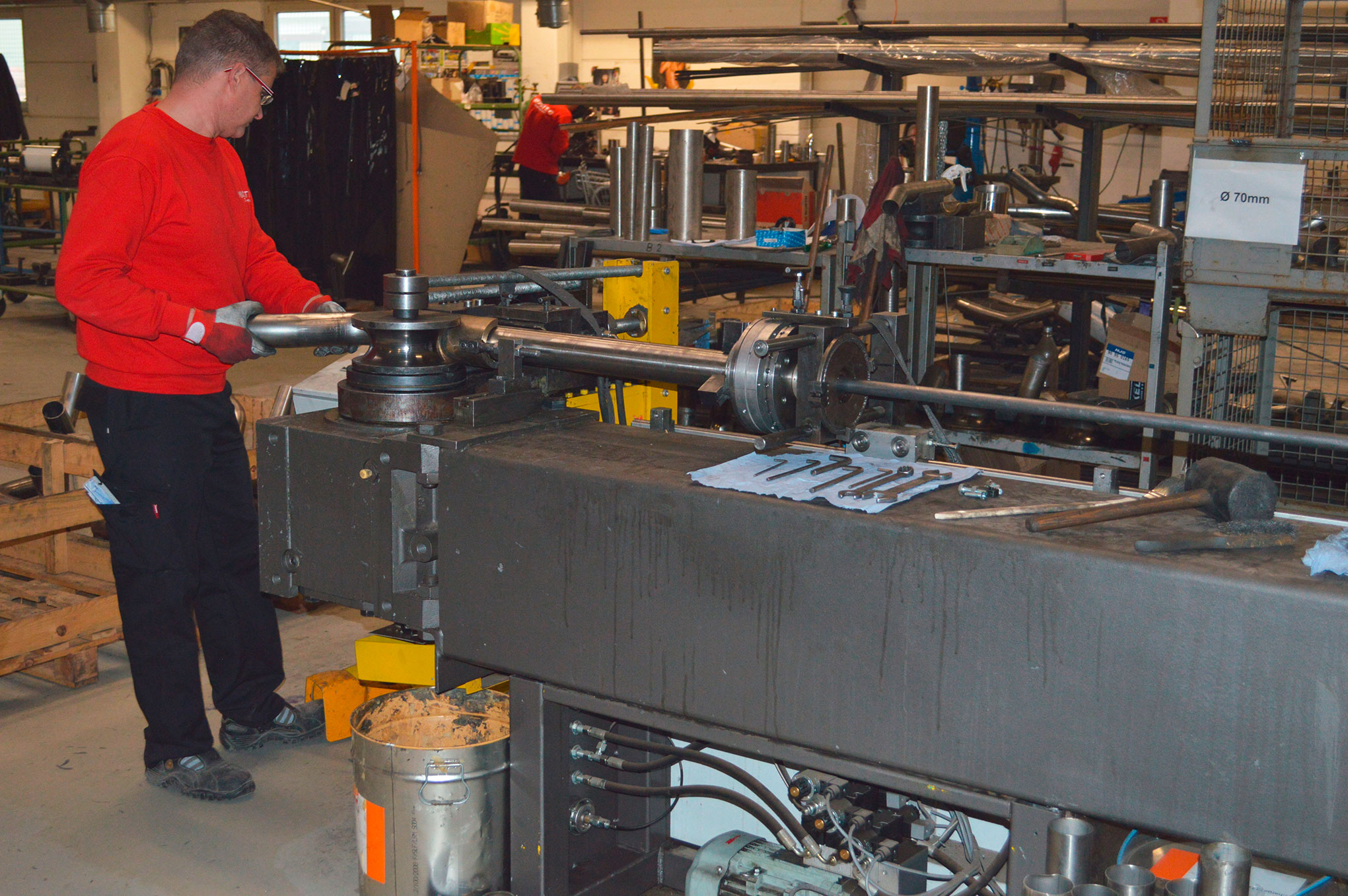

Pipe bending area

In addition to our semi-automated and fully automated bending machines, pipe material is stored here as well. We process cross section sizes from 44.5 - 114.3 mm.

Semi-automated bending machine

Our semi-automated bending machines are used primarily for prototyping and small lot-production. The bending cycle can be controlled automatically or manually. Tube feeding and tube rotation are manual.

Fully automated bending machine

The fully automated bending process bends, feeds, and rotates based on the selected bending programme. Series of 10 parts or more are made here.

.

Large bearing construction gauges

In this warehouse you will find all design templates for all assemblies such as downpipes, exhaust manifolds, front, middle and rear silencers as well as connecting pipes, adapters, brackets, etc.

Bearing construction gauges

The construction gauges for our rear silencers are located in this storage room. This storage room as well as the tailpipe storage room are located in the immediate vicinity of the welding stations.

Tailpipe bearing

For the individual design of our exhaust systems we offer approx. 100 different designs. To be flexible, we always have approx. 2.,000 tailpipes in stock.

Powder coating

Systems made of aluminised steel are powder-coated here to protect against surface corrosion. After cleaning the parts by sandblasting and washing, powder is applied and baked in the furnace.

Finished parts and shipping warehouse

Items such as downpipes, manifolds, pre-cat replacement pipes and dummies are prefabricated by us and temporarily stored here. These components can usually be shipped on the same day they are ordered. This warehouse also serves as intermediate storage for our general cargo and pallet shipments, which are picked up from us daily.

Welding place

We have 2 areas for welding stations. In one area, pipes and mufflers are assembled into a system, these parts then go to the intermediate storage for mufflers. The other area is located in close proximity to the muffler construction gauges and the tailpipe warehouse. This is where the final production of customer orders then takes place.

Intermediate storage - Silencer

After assembling the bent pipes and the muffler boxes, the systems are stored in this hall until further processing. Between 8.000 - 11.000 exhaust systems and mufflers are stored here at all times.

Shipping area

Prefabricated parts and individually produced systems come together here, assembly kits and expert opinions are completed here and packed ready for shipment. The final inspection also takes place here before the goods are shipped to our customers.