Friedrich Motorsport – Your specialist for exhaust systems!

Quality products from

stainless steel - chrome steel - aluminized steel

Products

MUFFLED AND POWERFUL SOUND

ABSORPTION TECHNOLOGY

REDUCED EXHAUST BACK PRESSURE

INDIVIDUAL TAILPIPE DESIGN

INCL. MOUNTING MATERIAL

REGISTRATION FREE WITH EG OPERATING LICENSE

In many vehicle classes, vehicles are visually differentiated according to equipment and engine by the number and positioning of the tailpipes at the rear of the vehicle. Many top models have so-called duplex systems with one or two tailpipes per side. Our duplex systems offer the possibility to upgrade the vehicle not only in terms of sound and performance, but also visually.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product.

Only in this way can we guarantee the well-groomed appearance of a sports silencer or tailpipe in the long term.

Not suitable and approved for import vehicles.

OPTIMIZED PIPE LENGTHS

INCREASED PIPE DIAMETER

INCREASE IN POWER AND TORQUE

1.4301 STAINLESS STEEL

WITH PARTS CERTIFICATE /

APPROVAL ACCORDING TO §19.3

The way a fan manifold works is that optimized pipe lengths and cross-sections result in better exhaust gas discharge. By generating a vacuum, the exhaust gases can escape from the combustion chamber with virtually no resistance when the exhaust valve is opened. The exhaust gases no longer have to be forced out by the piston, and fewer residual gases remain. This allows more fresh air to flow into the combustion chamber. This combination results in more power and torque.

In general, it is absolutely necessary for all materials to clean this regularly and, if necessary, to treat it with a suitable care product.

Only in this way can we ensure the well-groomed appearance of a sports silencer or tailpipe in the long term.

Not suitable and approved for import vehicles.

REPLACES THE ORIGINAL FRONT, MIDDLE AND REAR SILENCERS

DULL AND POWERFUL SOUND

ABSORPTION TECHNOLOGY

INCREASED PIPE DIAMETER

MORE POWER AND TORQUE

INDIVIDUAL TAILPIPE DESIGN

INCL. INSTALLATION MATERIAL

NO NEED FOR REGISTRATION WITH EC OPERATING PERMIT

REDUCED EXHAUST GAS BACK PRESSURE

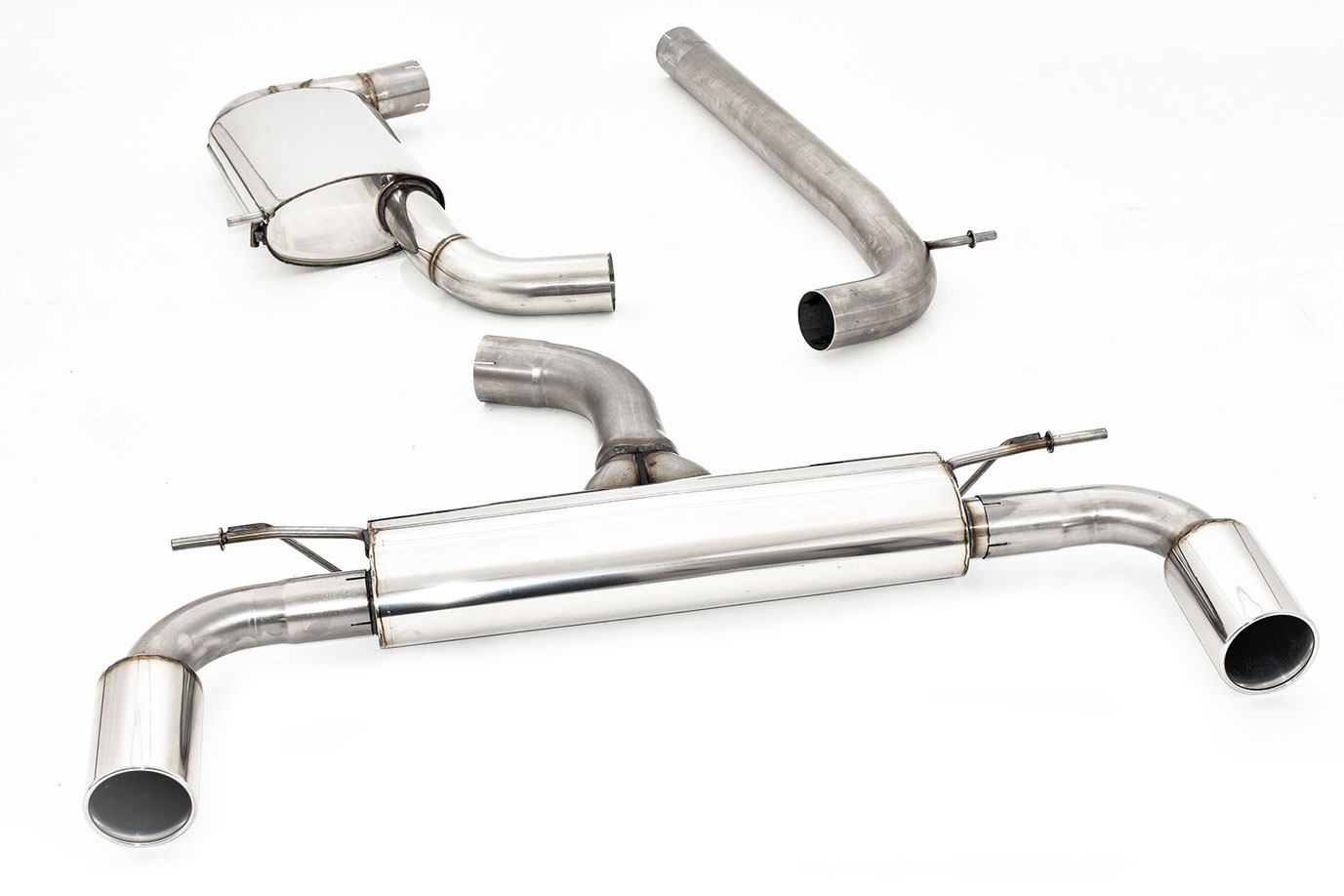

The term "Group A" has its origins in touring car racing, under this classification the specifications of racing cars. Typical for these vehicles were modified exhaust systems with increased pipe diameter (usually 63.5mm) and absorption design. This design results in a reduction of exhaust backpressure and thus an increase in torque and engine power. It also produces a powerful sound.

These systems can also be customized again with our various tailpipe designs.

Depending on the vehicle, we offer the items made of aluminized steel, chrome steel and stainless steel.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product.

Only in this way can we guarantee the well-groomed appearance of a sports silencer or tailpipe in the long term.

Not suitable and approved for import vehicles.

OPTICAL CHANGE AND UPGRADE OF THE VEHICLE

MUFFLED AND POWERFUL SOUND

ABSORPTION TECHNOLOGY

REDUCED EXHAUST BACK PRESSURE

INDIVIDUAL TAILPIPE DESIGN

INCL. MOUNTING MATERIAL

REGISTRATION FREE WITH EC TYPE APPROVAL

REDUCED EXHAUST BACK PRESSURE

Some vehicles are delivered from the factory with exhaust systems running off the center of the rear of the vehicle. Our 63.5mm, 70mm and 76mm systems are also available for these vehicles. In addition, we also offer the conversion to a central tailpipe outlet for selected vehicles.

In general, it is absolutely necessary for all materials to clean this regularly and, if necessary, to treat it with a suitable care product.

Only in this way can we ensure the well-groomed appearance of a sports silencer or tailpipe in the long term.

Not suitable and approved for import vehicles.

REPLACING THE ORIGINAL SILENCER

ABSORPTION TECHNOLOGY

MUDDY AND POWERFUL SOUND

INDIVIDUAL TAILPIPE DESIGN

INCL. INSTALLATION MATERIAL

REGISTRATION FREE WITH EC OPERATING APPROVAL

The original rear silencers are replaced with our sports rear silencers. The changed structure of the inner workings results in a duller, more powerful and therefore more sporty sound.

In addition to the sound, you can also change the rear view of your vehicle individually with our numerous tailpipe variants.

Depending on the vehicle, we offer items made of aluminized steel, chrome steel and stainless steel.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product.

This is the only way we can guarantee the well-groomed appearance of a sports silencer or a tailpipe in the long term.

Not suitable and approved for import vehicles.

In this section you will find all the accessories for turbo engines. This includes downpipes with and without sports cats., pre-cat and main cat replacement pipes, turbochargers and boost pressure pipes.

Not suitable and approved for import vehicles.

You can choose between the following materials:

INDIVIDUAL DESIGN OF YOUR OWN EXHAUST SYSTEM

BIG VARIETY

FROM 1 ¾ INCH (44.5MM) TO 3.5 INCH (88.9MM) DIAMETER

PIPE BENDS WITH 30°, 45°, 60° and 90°

ALUMINIZED STEEL AND STAINLESS STEEL

Unfortunately, it is not possible to offer fully developed sports exhaust systems for all vehicles. For customers with such vehicles, we offer our universal range of exhaust parts. In addition to pipes, pipe bends and clamps, we also offer flex baskets, flange connections and brackets.

With these components, the construction of an individual exhaust system can be implemented without much effort.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product.

This is the only way we can guarantee the well-groomed appearance of a sports silencer or a tailpipe in the long term.

Not suitable and approved for import vehicles.

1.4301 STAINLESS STEEL turbocharger and boost pressure pipes.

ABSORPTION TECHNOLOGY

ENLARGED PIPE DIAMETER

REDUCED EXHAUST BACKPRESSURE

MORE POWER AND TORQUE

INDIVIDUAL TAILPIPE DESIGN

INCL. INSTALLATION MATERIAL NON REGISTRATION WITH EC OPERATING APPROVAL

The 70mm systems are ideal for 4-cylinder turbo engines with displacements of up to 2.0l and for naturally aspirated engines with displacements of up to 3.0l. In a single-flow design, the systems can convert outputs of up to approx. 250 kW. Compared to 63.5mm Group A systems, these systems can generate more torque and achieve an even more powerful sound.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product. This is the only way we can guarantee the well-groomed appearance of a sports silencer or tailpipe over the long term.

Not suitable and approved for import vehicles.

IDEAL FOR TURBO ENGINES FROM 1.6L AND NATURALLY ENGINES WITH 8 OR 10 CYLINDERS

1.4301 STAINLESS STEEL

ABSORPTION TECHNOLOGY

ENLARGED PIPE DIAMETER

REDUCED EXHAUST BACKPRESSURE

PIPE BENDS WITH 30°, 45°, 60° and 90°

ALUMINIZED STEEL AND STAINLESS STEEL

Vehicles with turbo engines and more than 2.0l displacement as well as with 8-10 cylinder naturally aspirated engines already have pipe diameters of 60mm and larger ex works. We have developed our 1 and 2-flow 76mm systems for these vehicles. We approve these systems up to an output of approx. 330kW per exhaust line. Due to the enlarged tube cross-section and the optimized exhaust gas counter-pressure behavior, these systems are also suitable for performance increases.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product. This is the only way we can guarantee the well-groomed appearance of a sports silencer or tailpipe over the long term.

Not suitable and approved for import vehicles.

IDEAL FOR TURBO ENGINES FROM 2.5L DISPLACEMENT WITH 1-PASS EXHAUST SYSTEMS

1.4301 STAINLESS STEEL

ABSORPTION TECHNOLOGY

ENLARGED PIPE DIAMETER

REDUCED EXHAUST BACKPRESSURE

MORE POWER AND TORQUE

INDIVIDUAL TAILPIPE DESIGN

INCL. INSTALLATION MATERIAL NON REGISTRATION WITH EC OPERATING APPROVAL

We developed the 90mm systems for powerful production vehicles with 1-flow systems with a diameter of more than 76mm and for special tuning projects. The vehicles usually already have flap controls ex works, our systems continue to use these controls. The 90mm systems are suitable for increases in performance of up to approx. 450kW.

In general, it is absolutely necessary for all materials to be cleaned regularly and, if necessary, treated with a suitable care product. This is the only way we can guarantee the well-groomed appearance of a sports silencer or tailpipe over the long term.

Not suitable and approved for import vehicles.

15173

SATISFIED COSTUMERS

30

YEARS

13837

PRODUCTS

A QUICK LOOK AT PRODUCTION

- Factory

- Production

- Pipe bendingarea

- Bending machine

- Warehouse

- Coating

- Finished parts andshipping

- Welding place

- Intermediate storage - Silencer

- Shipping

Factory

The beginning and the end, combined in one of our factories. Here we build prototypes and new designs and assemble finished systems from our warehouse.

Production hall

Short distances are the key to a quick order processing. Everything comes together here. The raw material is right next to the processing machinery.

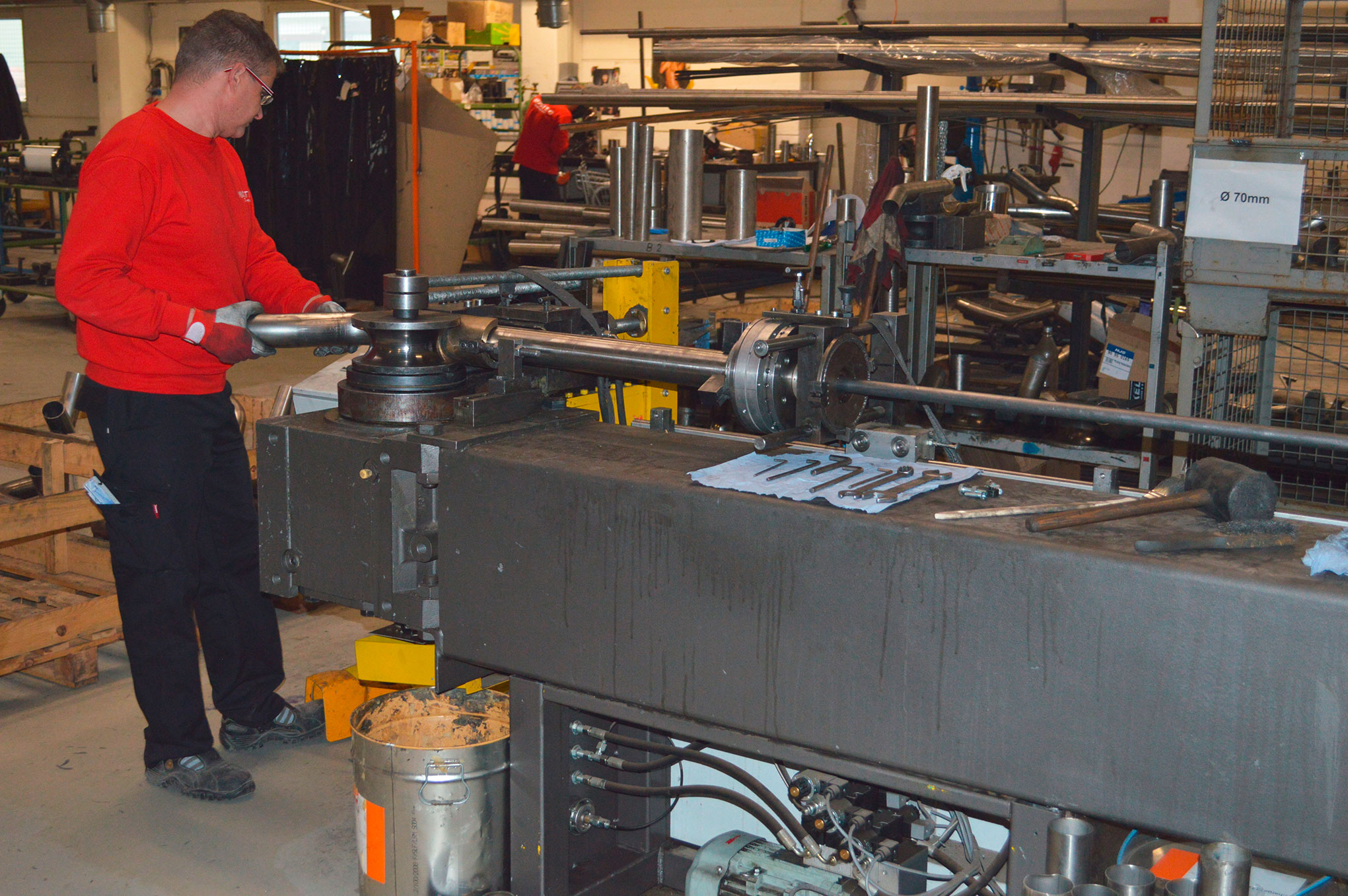

Pipe bending area

In addition to our semi-automated and fully automated bending machines, pipe material is stored here as well. We process cross section sizes from 44.5 - 114.3 mm.

Semi-automated bending machine

Our semi-automated bending machines are used primarily for prototyping and small lot-production. The bending cycle can be controlled automatically or manually. Tube feeding and tube rotation are manual.

Fully automated bending machine

The fully automated bending process bends, feeds, and rotates based on the selected bending programme. Series of 10 parts or more are made here.

.

Large bearing construction gauges

In this warehouse you will find all design templates for all assemblies such as downpipes, exhaust manifolds, front, middle and rear silencers as well as connecting pipes, adapters, brackets, etc.

Bearing construction gauges

The construction gauges for our rear silencers are located in this storage room. This storage room as well as the tailpipe storage room are located in the immediate vicinity of the welding stations.

Tailpipe bearing

For the individual design of our exhaust systems we offer approx. 100 different designs. To be flexible, we always have approx. 2.,000 tailpipes in stock.

Powder coating

Systems made of aluminised steel are powder-coated here to protect against surface corrosion. After cleaning the parts by sandblasting and washing, powder is applied and baked in the furnace.

Finished parts and shipping warehouse

Items such as downpipes, manifolds, pre-cat replacement pipes and dummies are prefabricated by us and temporarily stored here. These components can usually be shipped on the same day they are ordered. This warehouse also serves as intermediate storage for our general cargo and pallet shipments, which are picked up from us daily.

Welding place

We have 2 areas for welding stations. In one area, pipes and mufflers are assembled into a system, these parts then go to the intermediate storage for mufflers. The other area is located in close proximity to the muffler construction gauges and the tailpipe warehouse. This is where the final production of customer orders then takes place.

Intermediate storage - Silencer

After assembling the bent pipes and the muffler boxes, the systems are stored in this hall until further processing. Between 8.000 - 11.000 exhaust systems and mufflers are stored here at all times.

Shipping area

Prefabricated parts and individually produced systems come together here, assembly kits and expert opinions are completed here and packed ready for shipment. The final inspection also takes place here before the goods are shipped to our customers.